DownForce Education

Planter Downforce has changed throughout the years. In this page, we will try to explain the differences between different common downforce systems on the market and what to look for with each.

Function of Planter Downforce

One common misconception we hear is that downforce is what changes your depth. This is true that there can be a relationship between downforce and depth, however they are not always directly correlated. Ultimately the gauge wheels on the planter are what set the depth of the opener blade. The way that you directly control depth is through the mechanical linkage that sets the stop which the gauge wheel arms run up against when the row unit is lowered and running through the field. By adjusting this linkage, you are changing the relationship between your gauge wheels and the bottom of the seed openers, which in turn changes the "Theoretical" depth of the seed. This is theoretical, because it assumes that the disk openers are actually able to penetrate in the soil completely so that the gauge wheel arms contact the linkage in the first place. This is where downforce comes in.

The primary goal of downforce on a planter is simply to put enough pressure so that the disk opener gets completely down to the mechanically set depth, but not so much pressure so that the gauge wheels are causing the furrow to be compacted.

Lift Force

When we look at downforce on a planter, one commonly overlooked feature is the ability to have lift force on a row unit at times. As mentioned above, part of downforce management on a row unit is also to keep from putting too much downforce on the gauge wheels so that they start to compact the furrow which will cause hatchet roots resulting in inefficient nutrient use. (Instead of spreading out from the seed in a healthy way, the roots will only grow straight down in line with the base of the furrow in the shape of a hatchet) Because of this, there are times where it is actually very valuable for a row unit to have lift force. The biggest use case for this would be a box planter where you have a significant amount of weight on each row when the hoppers are full of seed. But this can also happen on a lighter row unit if conditions are a little on the wet side or if the ground it extra soft.

Downforce Management

The traditional method of managing downforce has always had to come down to going back and digging and checking how much pressure was on the gauge wheels. Ultimately going off of feel for where the downforce needed to be.

In the early 2000's, Precision Planting was the first company to bring to market the ability to add a load cell to planter rows giving feedback to exactly how much down pressure was resting on the gauge wheels of the planter at any given moment. At this point, we now had the ability to make an informed decision based on what this sensor value was telling us on how the downforce system should be adjusted.

Types of Downforce Systems

Below are the 3 most common types of downforce systems on planters and what distinguishes them from each other.

Spring Downforce

Spring Downforce has been around for years. This has typically been the standard feature on planters in the past. With spring downforce, there is typically one or multiple springs which are mounted on the planters parallel arms and put a constant pressure downwards on the row. These tend to be fairly inconsistent and can only be adjusted by going to each row and manually adjusting them. But they are simple and cheap.

Pneumatic DownForce

Pneumatic DownForce refers to whenever the downforce on a planter is being controlled through air bags on each row. This method is much more consistent than using springs. There are multiple "Levels" of this. The most common level is an air bag on each row which applies down force only to the rows. Traditionally, this type of system has been controlled through a manual valve in the tractor which the operator adjusts at his discretion. In 2008, Precision Planting released a system called Air Force which automatically adjusted the target downforce to the sensor readings on the load cells in order to maintain the desired down pressure resting on the gauge wheels. While this system was much better than the manual method from before, it is still a planter-wide control and limited by the time it takes for air bags to fill and vent. There is also a limit on how much overall force can be added due to the pressure rating on an air bat.

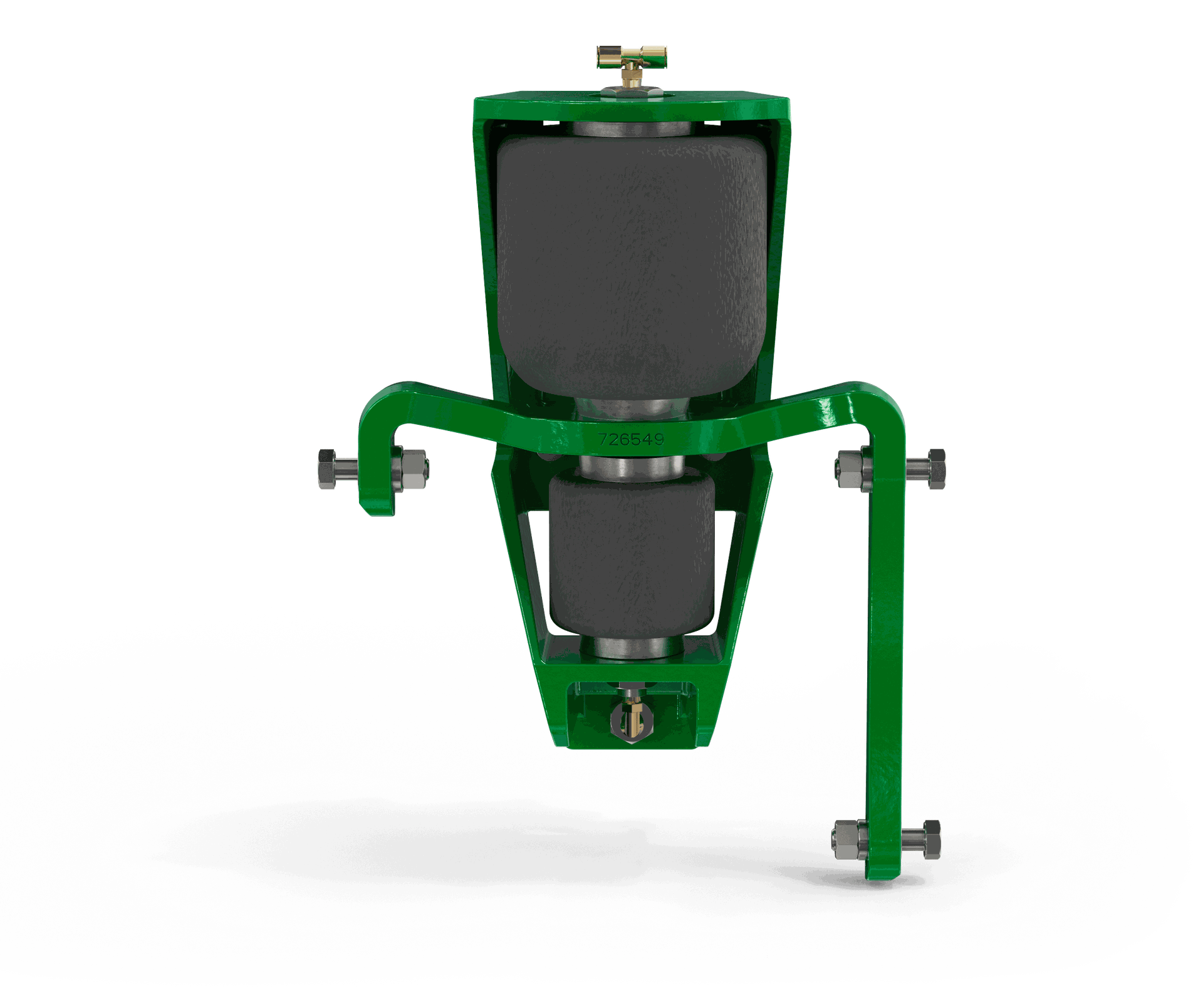

Hydraulic DownForce

Hydraulic Downforce is the next level from Pneumatic. In 2013 Precision Planting released DeltaForce which is row by row down and lift force controlled hydraulically. At this level, each row is using sensor readings coming in at 200 times per second to control at a speed of 5 times per second independently. This system has the ability to run it's entire range of downforce in only 1/2 of a second. This keeps each row perfectly tuned to the target pressure which is set in the cab. This allows rows to be able to adapt to their hyper-local environments and react to maintain the perfect downforce setting. Since DeltaForce came out, several other companies have also released their own versions of hydraulic downforce. Several of these other systems were only able to provide "Down" pressure and not "Lift" for quite a few years. As we mentioned above, this can be a very big deal and is something to research before buying a planter with downforce already on it.

Downforce Control

As listed above, we have many options for how to physically control the downforce on a planter. Now the question becomes, how do I know what to set my downforce to in the first place? Below are some general recommendations that we suggest. **Note: These are starting points. At the end of the day, it is always important to go out and do some digging to make sure you are where you want to be.

Setting a Manual system: To properly adjust a system which doesn't have any weight sensors to read, you will need to go by feel. A rule of thumb here is if you stop the planter after it's been running in field position, try to turn the gauge wheels. If you can't spin them by hand, then there is probably too much downforce. If the depth linkage is barely making contact, then the downpressure is too low. Note: when using spring downforce, each notch is typically around 100 lbs.

Setting with Load Cells on a Manual System

The Precision Planting load cell (John Deere and Ag Leader also have their own versions which read in slightly different ways) gives you Downpressure (the actual lbs which the gauge wheels are pushing down on the ground), Ground Contact (the percent in time that there is actually contact with the load cell), and Margin. Margin is the amount of extra or buffer weight that you could theoretically remove and still stay in the ground. On a manual spring or air system, you typically want the margin to be above 50 and below 100. With an automatic air system like Air Force, you have the option to set a range of pressure to to which the system reacts to. We like to make this range as tight as we can so that the reaction speed it as fast as it can be.

Setting with DeltaForce

With Deltaforce, because we are now controlling each row individually, instead of controlling it through margin, we now control it to exactly how much downpressure is resting on the wheels. On most planters, (JD, Kinze, White, Harvest IH) we like to start out around 100 lbs as the target. Then we use the ground contact values on the monitor to tune things to how we want. If ground contact is always pegged at almost 100%, then this may be an indication that we need to back it off a bit. A really good way to watch this is to pull up the downforce map on the Gen 3 20|20. On this map, it will show each row in high definition. Each time there is a blue dot, this indicates a moment of loss in ground contact. So typically we suggest trying to get the map as green as we can without seeing very many blue dots.